Thermal Gap Filler Pads

TGP1500

Naturally tacky with better thermal performance and ease of use across a multitude of applications. (Grey color, 0.94 Thermal Impedance, 1.5 Thermal Conductivity, Thickness 0.5 - 5 mm, Hardness 40 Shore 00)

Overview

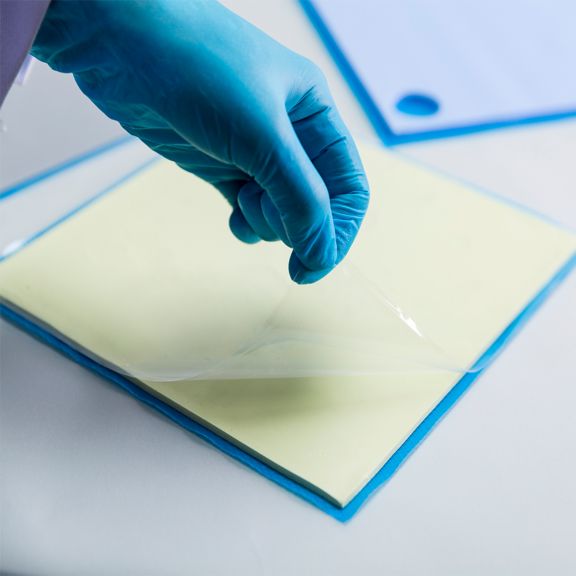

Honeywell Thermal Gap Filler Pads (TGPs) provide high thermal performance with ease of use for many applications. Ultra-high compressibility enables low stress and excellent conformity to mating surfaces. Honeywell TGP models are naturally tacky, and require no additional adhesive which could inhibit thermal performance. TGP models have been designed to minimize thermal resistance at interfaces, and maintain effective performance through reliability testing. TGP models are silicone based, therefore they offer a certain anti-shock effect, with electrical isolation and non-flammability.Typical Applications• Consumer electronics• Telecommunications & network servers• Automotive electronics• Power devices & modules• Semiconductor logic & memoryFeatures• High thermal performance• Ultra-high compressibility for low stress applications• Excellent surface wetting for low contact resistance• High reliability• Electrically insulating

Specifications

Physical Properties

- Color

- Grey

- Hardness

- 40 Shore00, Test Method ASTM D2240

- Shelf Life

- 12 months Year

- Specific Gravity

- 1.8, Test Method ASTM D792

- Thickness (mm)

- 0.5-5, Test Method ASTM D374

Thermal Properties

- Thermal Conductivity

- 1.5 W/m-K, Test Method ASTM D5470

- Thermal Impedance

- 0.94 °C·in²/W, 1 mm at 10 psi, Typical Value, Test Method ASTM D5470

Electrical Properties

- Dielectric Constant

- 5.5 at 1MHz, Test Method ASTM D150

- Volume Resistivity

- 2.0x1013 ohm-cm, Test Method ASTM D257

Flammability Properties

- Flammability

- V-0, Test Method UL94

General Information

- Application

- High Compressibility

- Key Features

- Cost effectiveness

- Typical Uses

- Consumer electronics

- Power devices & modules

- Semiconductor logic & memory

- Telecommunications & network servers

Physical Properties

- Color

- Grey

- Hardness

- 40 Shore00, Test Method ASTM D2240

- Shelf Life

- 12 months Year

- Specific Gravity

- 1.8, Test Method ASTM D792

- Thickness (mm)

- 0.5-5, Test Method ASTM D374

Thermal Properties

- Thermal Conductivity

- 1.5 W/m-K, Test Method ASTM D5470

- Thermal Impedance

- 0.94 °C·in²/W, 1 mm at 10 psi, Typical Value, Test Method ASTM D5470

Electrical Properties

- Dielectric Constant

- 5.5 at 1MHz, Test Method ASTM D150

- Volume Resistivity

- 2.0x1013 ohm-cm, Test Method ASTM D257

Flammability Properties

- Flammability

- V-0, Test Method UL94

General Information

- Application

- High Compressibility

- Key Features

- Cost effectiveness

- Typical Uses

- Consumer electronics

- Power devices & modules

- Semiconductor logic & memory

- Telecommunications & network servers

- Color : Grey

- Hardness : 40 Shore00, Test Method ASTM D2240

- Thickness (mm) : 0.5-5, Test Method ASTM D374

- Thermal Conductivity : 1.5 W/m-K, Test Method ASTM D5470

- Shelf Life : 12 months Year

- Specific Gravity : 1.8, Test Method ASTM D792

- Thermal Impedance : 0.94 °C·in²/W, 1 mm at 10 psi, Typical Value, Test Method ASTM D5470

- Dielectric Constant : 5.5 at 1MHz, Test Method ASTM D150

- Volume Resistivity : 2.0x1013 ohm-cm, Test Method ASTM D257

- Flammability : V-0, Test Method UL94

- Key Features : Cost effectiveness

- Typical Uses : Consumer electronics|Power devices & modules|Semiconductor logic & memory|Telecommunications & network servers

- Application : High Compressibility

Brochure

Name

Description

File Size

Date

Size

Thermal Interface Materials Electronics Brochure

application/pdf 820.98 KB

10/31/2023

820.98 KB

Name

Description

File Size

Date

Size

Thermal Interface Materials Electronics Brochure

820.98 KB

10/31/2023

820.98 KB

Name

Description

File Size

Date

Size

Thermal Interface Materials Electronics Brochure

820.98 KB

10/31/2023